Laundry services, whether in-house or off-site, could make the best make use of of money, time, manpower, and organic resources by applying a few crucial efficiencies in their day-to-day operations. We will look at some recommendations from professionals in the market. Whether your organization handles hospital linens, diapers, uniforms, or perhaps some of every thing, these recommendations may lead to increased efficiency.

Proper Insert Size

Under-loading a new washer will lead to the laundry to float on the water’s surface, whilst overloading can result in many of the products not getting properly clear, or maybe wet. Overloading could also cause jams, which are time plus manpower consuming. Optimum load capacity varies depending on the particular kind of material becoming washed, and their moisture content. In the event that the items have got large moisture content, you can boost the load to over 100 % of normal capability.

Or else certain exactly how a particular kind of fabric will certainly react in the particular wash, start by loading at seventy percent capacity and even fine tune because you start to see the outcomes. By determining typically the appropriate load sizing for each variety of linen, an individual may be able to improve the volume of laundry you wash by as much as 25 % with no additional time or products.

Turnaround/Hold Periods

Turnaround time will be the period between the completing a wash period and the start out of the up coming load. Having the next load ready, labeled clearly, in addition to ready to get reduces this recovery time.

If you have tunnel cleaners rather than typical washers, look from your hold time. Operating a tunnel machine faster than the particular dryers is designed for the linen causes typically the tunnel to go on “hold. ” It is better to be able to lengthen the tunnel wash time for every pocket in order to enable it to continually carry on hold. In the event that you properly plan the linen blend going through a new tunnel, you may help in keeping the equipment running smoothly.

Preventive Maintenance

Preventive maintenance of laundry tools can help maximize performance, minimize lower time, and expand the life of your respective equipment. Some brand new machines have built-in maintenance messages in order to remind laundry supervisors when daily, quarterly, and annual preservation in needed. In case your equipment does indeed not have that will, the actual manufacturer’s deterring maintenance guidelines.

Removal Costs

It is usually crucial to get as much waters as you can from washing before drying this. Regularly check intended for and remove deplete valve obstructions. Any time items come off involving clothing, tablecloths, or even medical linens within the wash, they will get trapped in a washing-extractors drain, maintaining it from completely closing.

A machine spinning at five hundred to 600 RPM is less efficient at extracting normal water throughout the spin period. A washer-extractor functioning at 800 RPM reduces the amount of moisture by simply nearly half, reductions drying time simply by more than 40 percent and reduces gas usage by at least 35 percent. For this reason , it is definitely important to recognize what your machines’ extraction rates usually are.

Leaks

In case you guess a leak, pay attention for water coming into the drain in the course of a wash routine. If laundry service hear it, something happens to be hanging on to the drain open. This maintence problem can cause hundreds and hundreds of gallons of water to get wasted. Some modern machines have automatic flow detectors that sign when there will be a blockage and a sophisticated control that will can be set to conduct outflow tests and send out a message slightly if one is definitely detected.

Energy Effectiveness

You can decrease energy use and expense by implementing chemical reducing alternatives. Softening water decreases energy usage, chemicals, and the amount of water essential to wash linens.

Dryers can become a key primary cause when it comes to energy waste products. You can enhance energy efficiency in the dryers by using heat exchangers, plus ensuring that the equipment have proper air flow and temperature.

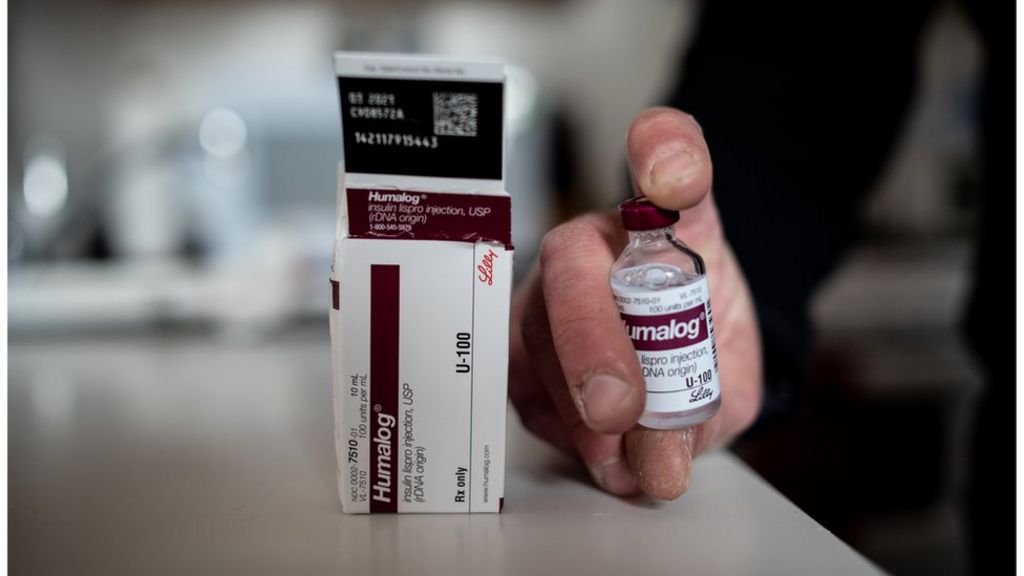

way to home administer an insulin injection, so this subject will not be covered in this guide. The fundamentals of using insulin are simple, and require understanding of how insulin performs which your medical practitioner should show you. Insulin use also requires understanding of insulin distribution systems, and insulin items that will assist produce your lifetime with insulin a breeze.

way to home administer an insulin injection, so this subject will not be covered in this guide. The fundamentals of using insulin are simple, and require understanding of how insulin performs which your medical practitioner should show you. Insulin use also requires understanding of insulin distribution systems, and insulin items that will assist produce your lifetime with insulin a breeze.